The client’s brief was to move the existing canning line out and locate it in a newly acquired brownfield factory in another country, all within one month!

Canning is an important part of the business and strategically the client wanted to centralise canning into one location leaving valuable room for another line in the doner site.

Planning started in April 2022, with initial surveys of the two sites, designing a layout and building a budget. Once Capex was approved, the project progressed at pace, writing the RFQ for the main contractor and agreeing all the work packages and working with the client’s team on the sundry elements of the move. (PD, QA, Compliance)

The Line relocation has been intense, documenting what we are moving, agreeing the scope of works with the main contractor and subcontractors. Planning with the doner factory the removal and the installation plan with the receiving site. Building and finessing the timeline multiple times as we sought ways to make the move happen in the target of 28 days that the client asked for. Controlling the variations to order. With a project of this sort, you must be flexible. There are so many unknows when you start to strip out a line, that a fixed price cost is not reasonable.

This has built to a crescendo of activity from the 1st Feb, when we started to dismantle and remove 52 pieces of the petfood canning line and 32 MCC’s.

On the timing plan, we had to be clear of doner site by the 10th Feb, to stand any chance of hitting the overall timeline of 28 days. The Main contractor had cleared the site in 7 days, at one point we had over 90 mechanics and electricians working in the doner site.

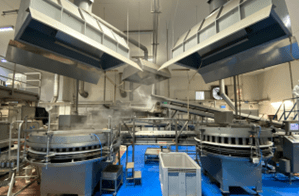

Line In Doner Site and Removal

The removal required over 40 trucks, with the Installation starting on the 3rd March at the receiving site and by the 13th March the majority of large machines was in place. With 100 people on site. 6 forklifts trucks, 8 Mobile access platforms and 2 cherry pickers a 200t crane and a 2000t crane due to the span of building we had to lift over.

Electrical reconnections from the MCC’s to field devices, connection from the main distribution boards to MCC’s and pipework from the boiler house, cooling tower, wastewater, soft water & compressed air all started in parallel with the equipment installation to save time. This brought time benefits and a few “head in hands” moments!

The building in the receiving site had to be adapted, roofs raised in three locations, walls removed, ceilings replaced, new lighting throughout and a general high level clean, luckily it was designed for “wet” process, so floor drains were already in. All the civil work was completed before the installation started.

I/O testing started on 20th March and wet commissioning on the 1st March. The teamwork has been exceptional, and the best part so far is no accidents. But 80% of the installation takes 50% of the available time with the remaining 20% taking the rest. This is normal as the details take time.

Line In New Site

Production restarted on the 5th March 2023, after quality and compliance checks had been completed. The ramp up has met its objectives and crucially no out of stocks occurred. The doner site has supported the new team very well, locating key personnel in the receiving site to ensure the new team understand the process and equipment and facilitating knowledge transfer.

4pM Ltd are proud to be associated with this client and project and are now working towards phase 2, which is an additional line.

Leave a comment